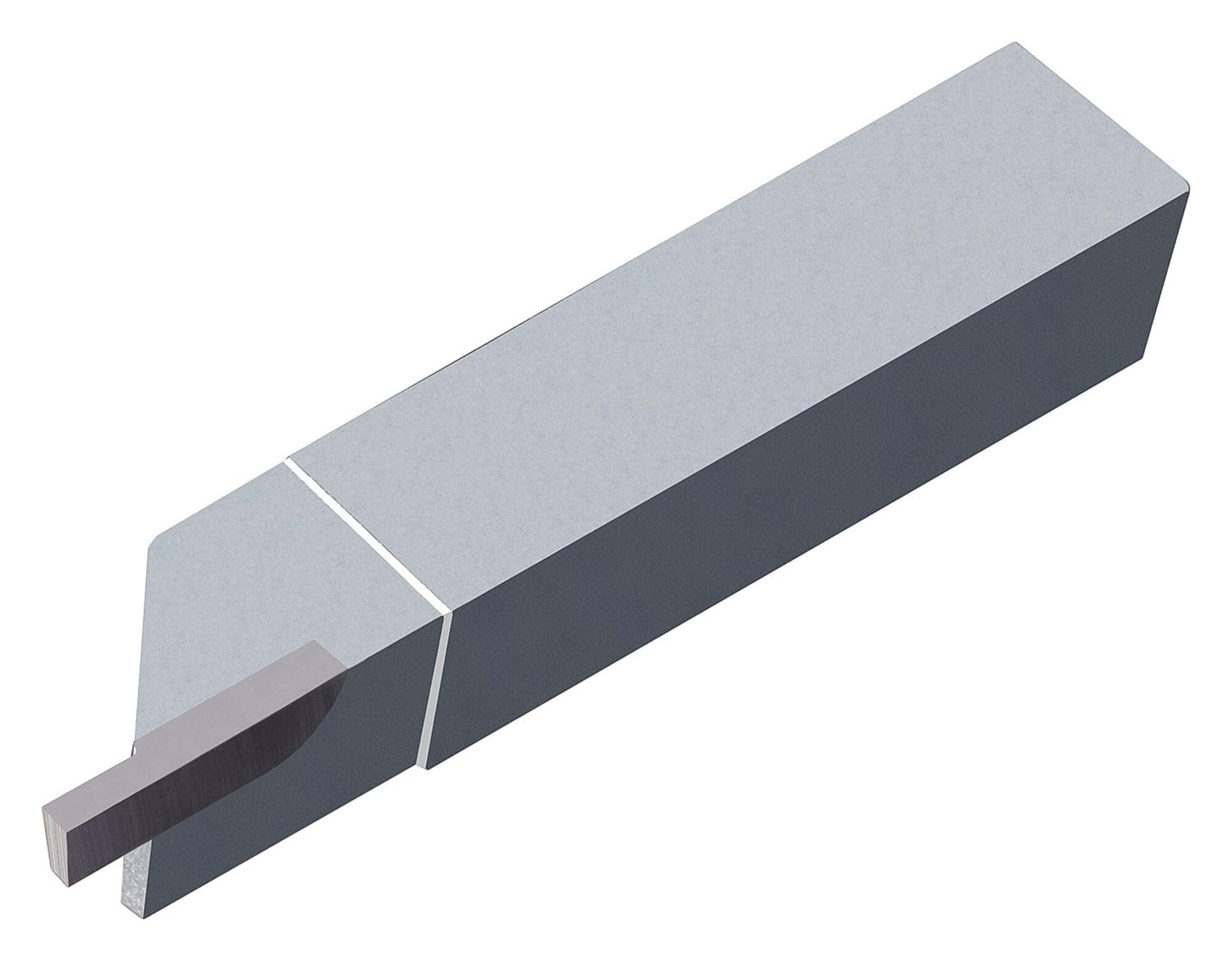

Brazed tools remain indispensable in the automotive and general machining industries, offering reliable performance where high rigidity and specific geometries are required. The products reviewed here, ranging from comprehensive turning sets to highly specialized cut-off and forming tools, represent the best options available in 2025, catering to both entry-level and expert machinists.

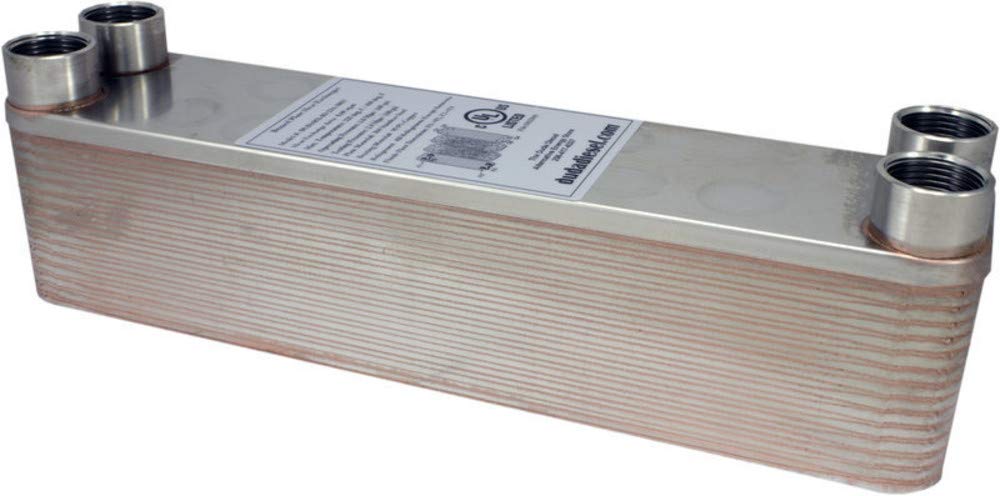

For general versatility and value, the 10-piece alloy carbide set is a strong contender. However, for precision tasks demanding exact tolerances—like those often found in high-quality automotive component manufacturing—investing in specialized Micro 100 tools ensures maximum accuracy and tool longevity. Even components like the Duda Energy Heat Exchanger showcase the critical role of copper brazing in high-performance applications.

Before making your final selection, carefully evaluate the shank size, tip material, and intended application. By prioritizing quality construction and matching the tool to the task, you can significantly improve your machining efficiency and the quality of your finished products. Upgrade your toolkit today with the confidence that you are choosing from the industry's top brazed tooling solutions.