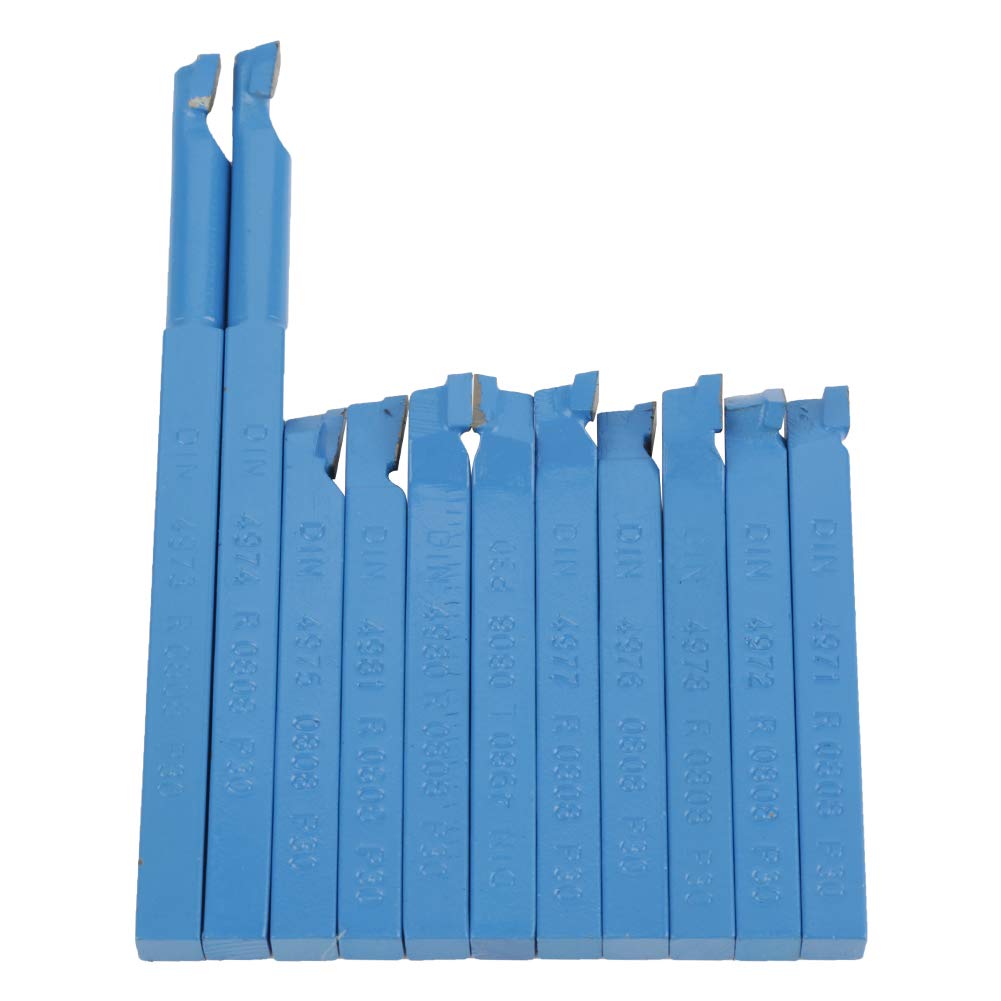

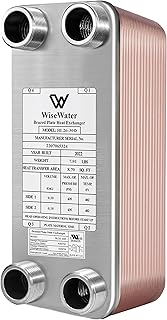

Brazed tools form the backbone of many precision and high-performance applications within the automotive and general metalworking industries. The strength derived from a properly executed brazed joint ensures that cutting tools retain their cutting tips under extreme pressure and that critical fluid systems, like heat exchangers, remain sealed and efficient.

When making your selection, prioritize tools that specify high-grade materials and verifiable brazing quality, whether you need a versatile 7-piece lathe set or a high-capacity 80-plate heat exchanger. Investing in quality, such as products from brands like Micro 100 or robust stainless steel exchangers, guarantees reliable performance and superior longevity, ultimately boosting productivity and the quality of your finished work. Review your specific needs against our detailed product guide to make the most informed purchase for 2025.